Plastic wrap的問題,我們搜遍了碩博士論文和台灣出版的書籍,推薦Beskow, Elsa寫的 Elsa Beskow Calendar 2023: 2023 和Allen, Brigette,Wong, Christine的 Breaking Up with Plastic: 100 Small Swaps to Lead a Plastic-Free Life都 可以從中找到所需的評價。

另外網站200 Sq Fair Trade Plastic Wrap - Whole Foods Market也說明:Find 365 Everyday Value® 200 Sq Fair Trade Plastic Wrap at Whole Foods Market. Get nutrition, ingredient, allergen, pricing and weekly sale information!

這兩本書分別來自 和所出版 。

國立成功大學 微電子工程研究所 張守進所指導 黃暐倫的 以濺鍍法製備氧化鎵系列金屬氧化物元件及其光電應用之研究 (2021),提出Plastic wrap關鍵因素是什麼,來自於金屬氧化物、氧化鎵系列材料、光檢測器、光電晶體、薄膜電晶體、電阻式記憶體。

而第二篇論文國立臺北科技大學 化學工程與生物科技系化學工程碩士班 蘇淵源所指導 廖婉婷的 非等溫複合纖維之界面不穩定模擬分析 (2021),提出因為有 共擠壓成型、複合纖維、溫度效應、包覆現象、界面不穩定的重點而找出了 Plastic wrap的解答。

最後網站Reynolds Kitchens Quick Cut Plastic Wrap - 225 Sq Ft - Target則補充:Great quality plastic wrap, and I like the cutter, it's a plastic slide type. Make sure to scan it from the Target app, there might be a discount. Did you find ...

Elsa Beskow Calendar 2023: 2023

為了解決Plastic wrap 的問題,作者Beskow, Elsa 這樣論述:

A spacious month-to-view wall calendar beautifully illustrated with Elsa Beskow’s vintage artwork.Elsa Beskow is one of Sweden’s best-known authors and illustrators. Her picture books have been loved for more than a century. This annual calendar is beautifully illustrated with Beskow’s delightful

seasonal illustrations of joyful children, charming wildlife, and magical little folk.The 2023 Elsa Beskow calendar: Includes US public holidaysGenerous space to add important dates, appointments, and family schedulesEco-friendly printing and plastic-free packagingIncludes illustrations from some o

f Beskow�s best-loved books - Ollie’s Ski Trip, Around the Year, Pelle’s New Suit, Children of the Forest and many more.New for 2023 - plastic-free packaging and eco-friendly printingThe 2023 Elsa Beskow calendar now comes beautifully presented in a sturdy cardboard envelope - no plastic shrink wrap

! Our eco-friendly printing processes include the use of sustainable (FSC) paper and plant-based inks, which reduce chemical emissions and make the calendar easier to recycle.

Plastic wrap進入發燒排行的影片

@リンネル チャンネル リンネル 11月号増刊 特別付録のオサムグッズのシリコーンケーキ型を使ってスノースキン月餅を作ってみました。見た目はスノースキン感は弱いですが、月餅🥮の型がなくても、シリコン型で作れたのがポイント。伸びのよい柔らかな餅皮とホワイトチョコのミルキー感がとっても合います。包みやすい餅皮なので同量の餡でも包みやすいです。型離れのポイントは打ち粉。片栗粉を型や餅皮の側面に多めに振ってください。くっつかずに作業できます。型に餅が貼り付き、1回、失敗してしまいました。

昔から大好きだったオサムグッズ。付録でシリコン型が手に入るなんていい時代なんだ。

*レシピ*(およそ64mlの型 6個分)

ホワイトチョコ餡を作ります

1.ホワイトチョコ 42gを溶かす。

2.白あん 150gを入れ混ぜる。

3.6等分にする。

4.お好みにパウダーで着色する。

今回、かぼちゃパウダー・紫芋パウダー・いちごパウダー 各2g、バタフライピーパウダー・抹茶 各1gで着色しています。もちろんそのままでもOKです。

5.ラップで丸く包み、冷蔵庫または冷凍庫で冷やしておく。

餅皮を作ります。

6.耐熱ボウルに白玉粉 24g、水 96gを入れ粒がなくなるまで混ぜる。

7.加糖練乳 24g、サラダオイル 24gと上新粉 24g、薄力粉 8g、上白糖 24gをあわせてフルイ入れ、泡立て器で混ぜる。

8.ふんわりラップをして、600wの電子レンジで50秒加熱し泡立て器で混ぜる。

9.その後、20秒加熱を3回繰り返し、その都度、泡立て器で混ぜる。

10.更に20秒加熱を3回繰り返し、その都度、今度はゴムベラで混ぜる。

11.更に今度はラップをしないで、1分30秒加熱し混ぜないでそのまま粗熱を取る。

12.片栗粉を広げたバットなどに(11)を6等分する。

13.ラップの間に(12)を伸ばす。

14.(5)を包む。

15.シリコン型に押し込む。

16.冷蔵庫で冷やす。

17.型から取り出す。

18.でけた。かわいいうまい。オサムグッズかわいい。永遠だな。

I made snow skin mooncakes using the silicone cake mold of OSAMU GOODS. It doesn't look like snow skin, but the key is that it can be made with a silicone mold even if you don't have a mooncake 🥮 mold.The milky texture of the white chocolate goes well with the soft and stretchy rice cake skin. Since it is a rice cake skin that is easy to wrap, it is easy to wrap even the same amount of bean paste. The key to mold release is flour. Sprinkle more potato starch on the sides of the mold and the rice cake skin. You can work without sticking. Mochi stuck to the mold and I failed once. I've always loved OSAMU GOODS. It's a good time to get a OSAMU GOODS silicone mold in a magazine freebie.

* Recipe * (for 6 molds of about 64 ml)

Make white chocolate bean paste.

1.Melt 42g of white chocolate.

2.Mix in 150g of white bean paste.

3.Divide into 6 equal parts.

4.Color with powder as desired. This time, I used 2g each of pumpkin powder, purple sweet potato powder, and strawberry powder, and 1g each of butterfly pea powder and matcha. Of course, you can leave them as they are.

5.Wrap in plastic wrap and chill in the refrigerator or freezer.

Make mochi skin.

6.Put 24g of Shiratamako and 96g of water in a heat-resistant bowl and mix until there are no grains.

7.Add 24g of sweetened condensed milk, 24g of salad oil, 24g of Joshinko, 8g of cake flour, and 24g of white sugar, and mix with a whisk.

8.Wrap it gently, heat it in a 600w microwave oven for 50 seconds, and mix it with a whisk.

9.Repeat heating for 20 seconds 3 times, mixing with a whisk each time.

10.Repeat heating for another 20 seconds three times, each time mixing with a rubber spatula.

11.Furthermore, without wrapping this time, heat for 1 minute and 30 seconds and remove the heat as it is without mixing.

12.Divide (11) into 6 equal parts on a tray with potato starch spread.

13.Spread (12) between sheets of plastic wrap.

14.Wrap (5).

15.Press into the silicon mold.

16.Chill in the refrigerator.

17.Remove from the mold.

18.It's done. Cute and delicious. OSAMU GOODS are eternal.

#SnowSkinMooncakes #recipe #月餅 #作り方 #オサムグッズ #リンネル #雑誌付録

以濺鍍法製備氧化鎵系列金屬氧化物元件及其光電應用之研究

為了解決Plastic wrap 的問題,作者黃暐倫 這樣論述:

Abstract in Mandarin IAbstract in English IVAcknowledgements VIIIContents XTable Captions XIVFigure Captions XVIChapter 1 Introduction 11-1 Overview of Metal Oxide Semiconductor 11-2 Overview of Ultraviolet Photodetectors 31-3 Overview of Thin Film Transistor 41-4 Overview of Resistiv

e Random-Access Memory 61-5 Organization of Dissertation 9Reference 11Chapter 2 Approaches of Measurement, Experimental Parameters, and Introduction of Experimental Instruments 172-1 Important Parameters for Ultraviolet Photodetectors 172-1-1 Responsivity 172-1-2 UV-to-visible Rejection Ra

tio 182-1-3 Photo-to-dark Current Ratio 182-2 Important Parameters for Thin Film Transistor 182-2-1 Threshold Voltage (Vt/Vth) 192-2-2 Field-Effect Mobility 202-2-3 On/off Current Ratio (Ion/Ioff) 222-2-4 Subthreshold Swing (SS) 222-3 Experimental Apparatus 232-3-1 Radio-frequency Sp

uttering System 232-3-2 Plasma-enhance Chemical Vapor Deposition (PECVD) 252-3-3 X-ray Diffraction Analysis (XRD) 252-3-4 Energy-Dispersive X-ray Spectroscopy (EDS) 282-3-5 X-ray Photoelectron Spectroscopy (XPS) 292-3-6 UV-vis Spectroscopy 302-3-7 Measurement Systems 30Reference 32Chap

ter 3 Investigation of Zinc Gallate Optoelectronics Device Prepared by RF Sputtering System 333-1 Motivation 333-2 Characteristics of Zinc Gallate Thin Film 333-2-1 Preparation of Zinc Gallate Thin Film 343-2-2 Analysis of Zinc Gallate Thin Film 353-3 Performance of Zinc Gallate UV Photode

tectors 413-3-1 Fabrication of Zinc Gallate UV Photodetectors 413-3-2 Results and Discussion 423-4 Performance of Zinc Gallate Thin Film Transistors 483-4-1 Fabrication of Zinc Gallate Thin Film Transistors 483-4-2 Results and Discussion 493-5 Summary 53Reference 55Chapter 4 Investigat

ion of Aluminum Gallium Zinc Oxide Optoelectronics Device Prepared by RF Sputtering System 574-1 Motivation 574-2 Characteristics of AGZO Thin Film 574-2-1 Preparation of AGZO Thin Film 584-2-2 Analysis of AGZO Thin Film 584-3 Performance of AGZO UV Photodetectors 644-3-1 Fabrication of

AGZO UV Photodetectors 644-3-2 Results and Discussion 654-4 Performance of AGZO Thin Film Transistors 734-4-1 Fabrication of AGZO Thin Film Transistors 734-4-2 Results and Discussion 744-5 Summary 81Reference 83Chapter 5 Investigation of Indium Gallium Oxide Optoelectronics Device Prepar

ed by RF Sputtering System 865-1 Motivation 865-2 Characteristics of Indium Gallium Oxide Thin Film 865-2-1 Preparation of Indium Gallium Oxide Thin Film 865-2-2 Analysis of Indium Gallium Oxide Thin Film 875-3 Performance of Indium Gallium Oxide UV Photodetectors 915-3-1 Fabrication of

Indium Gallium Oxide UV Photodetectors 915-3-2 Results and Discussion 925-4 Performance of Indium Gallium Oxide Thin Film Transistors 965-4-1 Fabrication of Indium Gallium Oxide Thin Film Transistors 965-4-2 Results and Discussion 985-5 Summary 104Reference 106Chapter 6 Investigation of

Indium Gallium Oxide Non-volatile RRAM Prepared by RF Sputtering System 1086-1 Motivation 1086-2 Characteristics of InxGa1-xO Thin Film 1096-2-1 Preparation of InxGa1-xO Thin Film 1096-2-2 Analysis of InxGa1-xO Thin Film 1106-3 Performance of single layer InGaO RRAM 1136-3-1 Fabrication

of single layer InGaO RRAM 1136-3-2 Results and Discussion 1146-4 Performance of Stacked InxGa1-xO RRAM 1236-4-1 Fabrication of Stacked InxGa1-xO RRAM 1236-4-2 Results and Discussion 1246-5 Summary 130Reference 132Chapter 7 Conclusion and Future Work 1347-1 Conclusion 1347-2 Future W

ork 136

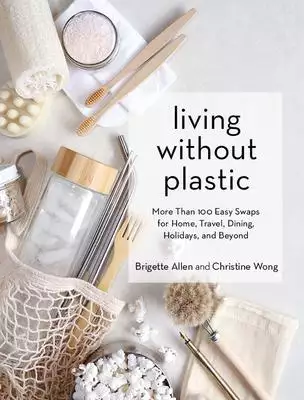

Breaking Up with Plastic: 100 Small Swaps to Lead a Plastic-Free Life

為了解決Plastic wrap 的問題,作者Allen, Brigette,Wong, Christine 這樣論述:

Every year, the world produces more than 300 million tons of plastic. These products will never break down and will endlessly pollute our oceans, air, land, and food chain. But the good news is that there are many steps, small and large, we can take to change our plastic-using habits. This illustrat

ed book offers more than 100 suggestions in an accessible visual and gifty package. The introductory chapter walks readers through the different types of plastic and terminology. Then, starting with two of the most prevalent problems--the plastic water bottle and the plastic shopping bag--the book c

ontinues with the actions we can take each day to achieve a plastic-free life, organized into thematic lifestyle categories covering food, health and beauty, home, special occasions, and more. The information is presented in short actionable text, and each entry includes facts to help the reader und

erstand why the change is a good one. Swap your to-go cup for a reusable mug or invest in metal straws; learn how to DIY your cleaning products, party decorations, and grocery bags; incorporate alternatives to plastic wrap, take-out containers, commercial cosmetic products, cotton balls, and water f

ilters; find out how to avoid the toxins released from the plastic in your refrigerator, shampoo bottles, clothing, and office supplies. Breaking Up with Plastic is a straightforward manual that promises readers a thorough guide to ending their relationship with plastic for good. Brigette Allen is

an experienced oceans advocate and former director of partnerships for Plastic Ocean International. Now with her own consultancy business, Allen taps into her experience as a former investment banker and venture capitalist to help companies implement scalable solutions to the plastic problem in the

personal care, food and beverage, and travel space.Christine Wong is a plant-based-food blogger who advocates for zero-waste consumption and eco-friendly choices within the kitchen and home. Follow her on Instagram @conscious_cooking and with the hashtag #plasticfreefoodie.Plastic Ocean Internation

al (POI) is a nonprofit organization whose mission is to inspire behavioral change to end plastic pollution everywhere. Follow them on Instagram and Facebook @plasticoceans.

非等溫複合纖維之界面不穩定模擬分析

為了解決Plastic wrap 的問題,作者廖婉婷 這樣論述:

界面不穩定及包覆行為時常是分割型複合纖維中的一大罩門,本研究著重探討兩大研究問題,材料採用聚丙烯及聚醯胺,並選擇PTT model作為本質方程式來探討黏彈性流體之各項參數對其影響,除此之外,結合了能量方程式,使用Arrhenius law描述各項材料之溫度的影響,分別探討等溫及非等溫之間的差異,並一一說明黏度效應、彈性效應、剪切應力、流量比值等各項參數在兩大問題中所影響的程度。我們發現到,溫度的加入與高分子的黏性效應有個不可分離的密切關係,而彈性的增長可以帶來包覆情形的額外助力,且不需依靠黏度的差異即可達到預期效果。另外,在界面變化上面,模具的尺寸則使剪切應力的影響更加明顯,特別在兩者流體剛

匯流的位置與進入最小截面積之紡口直管時,波浪型界面不穩定最為顯著,故可以依照溫度的加入來改變黏度、彈性、剪切應力等參數來使不穩定的情形減弱,讓包覆現象的趨勢也能達到所需結果,使塑料得以順利在出紡口後分離,且為共擠壓成型加工上帶來更實際的參考依據。

想知道Plastic wrap更多一定要看下面主題

Plastic wrap的網路口碑排行榜

-

#1.The 5 best plastic wrap alternatives - Mic

When it comes to the best plastic wrap alternatives, the most common options are beeswax wraps, silicone lids, and cloth covers. The right one ... 於 www.mic.com -

#2.How to reduce plastic wrap use in your home kitchen - The ...

Cheap and convenient, plastic wrap unfortunately does its job well. You'll find it littered throughout recipes to wrap foods for later, cover a ... 於 www.washingtonpost.com -

#3.200 Sq Fair Trade Plastic Wrap - Whole Foods Market

Find 365 Everyday Value® 200 Sq Fair Trade Plastic Wrap at Whole Foods Market. Get nutrition, ingredient, allergen, pricing and weekly sale information! 於 www.wholefoodsmarket.com -

#4.Reynolds Kitchens Quick Cut Plastic Wrap - 225 Sq Ft - Target

Great quality plastic wrap, and I like the cutter, it's a plastic slide type. Make sure to scan it from the Target app, there might be a discount. Did you find ... 於 www.target.com -

#5.Plastic Wrap with Slide Cutter | Reynolds Brands®

Swap out your frustrating cling wrap with Reynolds KITCHENS® Quick Cut™ Plastic Wrap. Try our plastic wrap with slide cutter to get that clean edge. 於 www.reynoldsbrands.com -

#6.Plastic Wrap - Order Online & Save | Stop & Shop

Wide assortment of Plastic Wrap and thousands of other foods delivered to your home or office by us. Save money on your first order. 於 stopandshop.com -

#7.Commercial Plastic Wrap | TundraFMP Restaurant Supply

Get plastic wrap for your commercial business, & find more food wrap at TundraFMP Restaurant Supply. 於 www.etundra.com -

#8.The Foolproof Restaurant Trick for Using Plastic Wrap

Learn how to keep dishes properly covered in plastic cling wrap with these quick and easy instructions for the hotel wrap. 於 www.epicurious.com -

#9.How does cling wrap cling? - Gizmodo

Plastic wrap hangs on to everything it touches like grim death. Find out how it manages to glom on to nearly every surface in a kitchen. 於 gizmodo.com -

#10.Plastic packaging | WRAP

Plastic packaging in the UK accounts for nearly 70% of our plastic waste, making packaging the primary focus of The UK Plastics Pact Find out more 於 wrap.org.uk -

#11.Fisherbrand™ Clear Plastic Wrap - Fisher Scientific

Designed specifically for the laboratory Shop Fisherbrand™ Clear Plastic Wrap at Fishersci.com. 於 www.fishersci.com -

#12.Plastic wrap storage hack, why you should store it in the freezer

Many people store plastic wrap in kitchen drawers (right next to the aluminum foil, plastic baggies and parchment paper, of course) but it ... 於 www.today.com -

#13.H-E-B Texas Tough Plastic Wrap - Shop Food Storage ...

Shop H-E-B Texas Tough Plastic Wrap - compare prices, see product info & reviews, add to shopping list, or find in store. Select locations now offer ... 於 www.heb.com -

#14.3 Eco-Friendly Alternatives to Plastic Wrap - MightyNest

It's true, this one seems tricky; replacing the oh-so-easy cling wrap (this is made with LPDE plastic, a low density polyethylene) with a viable ... 於 mightynest.com -

#15.PLASTIC WRAP在劍橋英語詞典中的解釋及翻譯

plastic wrap 的意思、解釋及翻譯:1. thin, transparent, plastic material, used for wrapping food to keep it fresh: 2. thin…。了解更多。 於 dictionary.cambridge.org -

#16.18 in. x 1470 Ft High Performance Stretch Wrap - Harbor Freight

Amazing deals on this 18In X 1470Ft Stretch Wrap at Harbor Freight. Quality tools & low prices. 於 www.harborfreight.com -

#17.Why You Should Store Plastic Wrap in the Freezer - Good ...

The problem: Cling wrap, well, clings. It's so good at its job that it sometimes make your job (sealing up leftovers) a total pain. 於 www.goodhousekeeping.com -

#18.Plastic Wrap | Walgreens

Plastic Wrap at Walgreens. View current promotions and reviews of Plastic Wrap and get free shipping at $35. 於 www.walgreens.com -

#19.The Pioneer Woman Plastic Wrap Dispenser

Our favorite plastic wrap dispensers are now available in our favorite Pioneer Woman florals! These Mercantile exclusive dispensers cling to pretty much ... 於 www.themercantile.com -

#20.Plastic wrap - The Free Dictionary

plastic wrap. n. Plastic that is formed into a thin, clear, flexible sheet and used as a wrapping to keep food from spoiling. 於 www.thefreedictionary.com -

#21.Great Wrap: 100% Compostable Cling Wrap | Eco Friendly ...

Great Wrap offers Australian made compostable eco-friendly cling wrap made by diverting food waste at great prices. No Microplastics & breaks down within ... 於 www.greatwrap.co -

#22.8 Surprising Uses for Plastic Wrap - House Beautiful

Try this tip from The Ugly Duckling House and wrap your wet paint rollers in plastic wrap. She promises it will make daily clean-up so much ... 於 www.housebeautiful.com -

#23.How to Use Plastic Wrap When Moving

The plastic wrap will only help keep protective materials in place. Once you're ready to get wrapping, have another person hold the item still ... 於 www.moving.com -

#24.Colored Plastic Film, Colored Stretch Wrap in Stock - ULINE

Uline stocks 7 colors of Stretch Wrap, Stretch Film and Pallet Wrap. Order by 6 pm for same day shipping. Huge Catalog! Over 38500 products in stock. 於 www.uline.com -

#25."clingfilm" 和"plastic wrap" 的差別在哪裡? | HiNative

In Canada, at least, we also say saran wrap very commonly! Haha even though Saran is the trademark. I don't know if that's the case in the ... 於 hinative.com -

#26.IGA Plastic Wrap Clear | Food Storage - MyIGA.com

Order online IGA Plastic Wrap Clear on www.myiga.com. 於 www.myiga.com -

#27.plastic wrap - Amazon.com

18" Stretch Film/Wrap 1200ft 500% Stretch Clear Cling Durable Adhering Packing Moving Packaging Heavy Duty Shrink Film (1 Pack, Clear). 於 www.amazon.com -

#28.This New, Plastic-Free Cling Wrap Breaks Down Quicker Than ...

Great Wrap is a plant-based alternative to the handy kitchen staple – and it can go straight into your home compost system or green-waste ... 於 www.broadsheet.com.au -

#29.Plastic Wrap Science Fair Project: Polymer Permeability

In this plastic wrap science fair project, you'll learn about polymer permeability and find out which plastic wrap keeps food from dehydrating best. 於 www.education.com -

#30.Packaging – Plastic Wrap - Michigan State University

Plastic wraps are typically clear or lightly colored transparent food-safe coverings that cling to themselves and to food containers to form ... 於 www.canr.msu.edu -

#31.Berkley Jensen 12" x 3000' Plastic Film Wrap - Clear - BJ's ...

Buy Berkley Jensen 12" x 3000' Plastic Wrap Film from BJ's Wholesale Club. Great for covering bowls to prevent splatters in the microwave. 於 www.bjs.com -

#32.Plastic wrap - Wikipedia

Plastic wrap, cling film, Saran wrap, cling wrap, Glad wrap or food wrap is a thin plastic film typically used for sealing food items in containers to keep ... 於 en.wikipedia.org -

#33.Food Plastic Wrap 家用保鮮膜不加熱也潛藏危機?!

Plastic wrap or cling wrap is a common household item; even stores use them to package food. Most of the plastic warp is made from polyvinyl ... 於 www.am1470.com -

#34.Cling Wrap and Plastic Food Wrap - WebstaurantStore

Keep food fresh with plastic food wrap & cling film in bulk for your commercial kitchen! Get wholesale pricing & fast shipping from WebstaurantStore! 於 www.webstaurantstore.com -

#35.Stop Wasting Your Money on Plastic Wrap

SuperBee Beeswax Wraps are a great money saving alternative to plastic wrap – not only are they affordable, but they are reusable, last for up ... 於 superbee.me -

#36.Why You Shouldn't Keep Plastic Wrap in a Drawer - Reader's ...

That sticky ball of plastic wrap isn't doing anyone any good. Stop ruining your plastic wrap with this simple trick. 於 www.rd.com -

#37.Plastic wrap saves your sandwich but pollutes the planet. Is ...

By the 1960s, the Australian company GLAD had created its own—though less clingy—version of plastic wrap from polyethylene. Saran Wrap too is ... 於 www.nationalgeographic.com -

#38.How to recycle plastic film/wrap - The City of Calgary

Drop off at a community recycling depot for free. What items are made out of plastic film? Plastic film; Cling wrap; Glad stretch wrap; Saran ... 於 www.calgary.ca -

#39.plastic wrap - 英中– Linguee词典

大量翻译例句关于"plastic wrap" – 英中词典以及8百万条中文译文例句搜索。 ... Cover the food with a microwave safe lid / plastic wrap; however, leave a small ... 於 cn.linguee.com -

#40.Plastic wrap Definition & Meaning | Dictionary.com

Plastic wrap definition, a very thin, transparent sheet of plastic, usually packaged in rolls and often having the ability to cling to other substances, ... 於 www.dictionary.com -

#41.6 Best Alternatives for Plastic Wrapping and Packaging

Plastic wrap has been a convenient product but there are better options now. Read on to discover eco-friendly alternatives to plastic ... 於 www.bioenergyconsult.com -

#42.Plastic wrap combined with alcohol wiping is an effective me...

This study evaluated the effectiveness of plastic wrapping in decreasing bacterial contamination on mobile phone surfaces. Method: We used ... 於 journals.lww.com -

#43.The History of Saran Wrap - ThoughtCo

The Saran films introduced by the Dow Chemical Company are best known as Saran Wrap. In 1949, it became the first cling wrap designed for ... 於 www.thoughtco.com -

#44.synonyms for plastic wrap - Thesaurus.com

Find 4 ways to say PLASTIC WRAP, along with antonyms, related words, and example sentences at Thesaurus.com, the world's most trusted free thesaurus. 於 www.thesaurus.com -

#45.20” Mover's Stretch Plastic Wrap | U-Haul

This plastic stretch/moving wrap has hundreds of uses, from wrapping a dresser or cabinet to keep the doors and drawers in place, to bundling items together ... 於 www.uhaul.com -

#46.Plastic Wrap - Order Online & Save - Giant Food

Wide assortment of Plastic Wrap and thousands of other foods delivered to your home or office by us. Save money on your first order. 於 giantfood.com -

#47.Testing Plastic Wrap - Cook's Illustrated

The Tests. Use to wrap vessels of different materials (metal, glass, and plastic bowls, plus our favorite broiler-safe ceramic baking dish) ... 於 www.cooksillustrated.com -

#48.30 M Plastic Wrap - IGA

Prices valid from Thursday November 18 2021 to Wednesday November 24 2021. << Back to search results. Compliments ... 於 www.iga.net -

#49.Plastic Wrap for sale | eBay

Get the best deals on Plastic Wrap when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands ... 於 www.ebay.com -

#50.Stretch wrap Packing Supplies at Lowes.com

Find Stretch wrap packing supplies at Lowe's today. Shop packing supplies and a variety of storage & organization products online at Lowes.com. 於 www.lowes.com -

#51.plastic wrap - 用法 - 海词词典

plastic wrap 的用法和樣例:. 例句. As the food is nuked, the high heat causes poisonous toxins to actually melt out of the plastic wrap drip into the ... 於 dict.cn -

#52.60 Plastic Wrap ideas | cookie packaging, food ... - Pinterest

Oct 10, 2017 - Explore Heliosphere Solutions's board "Plastic Wrap" on Pinterest. See more ideas about cookie packaging, food packaging, bakery packaging. 於 www.pinterest.com -

#53.Wrap & Move 500mm x 280m Clear Pallet Shrink Wrap

Features · Safe and easy use for postage and handling · Multi purpose usage for moving and storage · Shrink wrap for large packaging · 500mm width · 280m roll length. 於 www.bunnings.com.au -

#54.Plastic Wrap Images, Stock Photos & Vectors | Shutterstock

Find plastic wrap stock images in HD and millions of other royalty-free stock photos, illustrations and vectors in the Shutterstock collection. 於 www.shutterstock.com -

#55.plastic wrap - Longman Dictionary

plastic wrap meaning, definition, what is plastic wrap: thin transparent plastic used to cover f...: Learn more. 於 www.ldoceonline.com -

#56.Nan Ya Plastics PVC wrap PVC wrap film PVC cling wrap ...

Nan Ya PVC wrap film hygiene and safety, glossiness and transparency, ... PVC Cling Film ... It was suitable for all sorts of foods packaging. 2. 於 www.npc.com.tw -

#57.Recycle Plastic Wrap at Your Local Grocery! | East Hartford CT

Did you know that plastic wrap like produce bags, shipping envelopes, newspaper bags, packaging, and drycleaning bags ca. 於 www.easthartfordct.gov -

#58.Plastic Wrap Pictures, Images and Stock Photos - iStock

Roll of wrapping plastic stretch film. Close-up with selective focus and Shallow Depth of Field. Isolated on white background. 於 www.istockphoto.com -

#59.'plastic wrap' 的简体中文Translation | 柯林斯英语- 汉语词典

'plastic wrap' 的简体中文Translation of | 官方柯林斯英语- 汉语词典网上词典。10 万条英语单词和短语的简体中文翻译。 於 www.collinsdictionary.com -

#60.The best alternatives to plastic wrap - green+simple

Change your habits bit-by-bit starting with these plastic wrap alternatives. Beeswax wraps. Beeswax wraps are one of the simplest and easiest cling wrap swaps ... 於 greenandsimple.co -

#61.Kirkland Signature Stretch-Tite Plastic Food Wrap, 11 7/8 in x ...

... From freezer to fridge to microwave, handles all environments; Kirkland Signature™ Stretch-Tite® Premium Plastic Food Wrap is Proudly Made in the USA ... 於 www.costco.com -

#62.NAN YA Plastic Wrap | The Leading Plastics Manufacturer in ...

Formosa food wrap company, food wrap manufacturer, cling wrap supplier in Asia, has been around for nearly 40 years. With production bases in Vietnam, ... 於 www.nanya-wrapfilm.com -

#63.Why Does Plastic Wrap Cling To Itself? - Indiana Public Media

Most thin plastic films easily pick up a static electric charge by friction. In other words, plastic wrap is static electricity waiting to ... 於 indianapublicmedia.org -

#64.Boulder Plastic Wrap | ALDI US

Boulder Plastic Wrap. Boulder Plastic Wrap. Amountsee price in store* Quantity 200 ft. selected Description. Description ... 於 www.aldi.us -

#65.Plastic Wrap 101 ~ All About Plastic Cling Wrap! - US ...

Food plastic wrap, also known as cling film, food wrap, and saran wrap, is a thin plastic film commonly used for sealing and securing food items in containers ... 於 uspackagingandwrapping.com -

#66.Plastic Wrap - Walmart.com

Shop for Plastic Wrap in Paper & Plastic. Buy products such as Glad Freezer Wrap Plastic Food Wrap, 150 Square Feet at Walmart and save. 於 www.walmart.com -

#67.25 Clever Uses for Plastic Wrap You'll Wish You Knew Sooner

Plastic wrap uses go far beyond keeping leftovers fresh! Save time, money and effort with these genius plastic wrap hacks. 於 www.readersdigest.ca -

#68.Plastic wrap Definition & Meaning - Merriam-Webster

The meaning of plastic wrap is thin, clear plastic that is used to wrap food or to cover containers that have food in them. 於 www.merriam-webster.com -

#69.Stretch Wrap & Shrink Wrapping Supplies | Staples®

Per the name, stretch wrap is stretched around items when packaging them together. It's highly elastic and wraps tightly for a secure, no-move wrapping. On the ... 於 www.staples.com -

#70.The Plastic Wrap Trick Restaurant Pros Swear By | MyRecipes

... game changer for the home cook as well. Cling to this trick to become a true (plastic) wrap legend... and keep your food fresher, longer. 於 www.myrecipes.com -

#71.Plastic Wrap - Amazon.in

1-48 of over 60,000 results for "Plastic Wrap" · The absolutely best food wrappers to get. Jul 25, 2020 - 5 · Read full article. Best overall ... 於 www.amazon.in -

#72.How plastic wrap is made - material, manufacture, making ...

Background. Plastic wrap is a form of food packaging consisting of a thin film of flexible, transparent polymer that clings to itself and to food containers ... 於 www.madehow.com -

#73.SealWrap Plastic Wrap - Canadian Tire

Plastic wrap is an all purpose food wrap; Includes Zipsafe; 1000' x 11' (2540 x 28 cm); Measures 304 m x 28 cm (1000' x 11") ... 於 www.canadiantire.ca -

#74.Plastic Wrap & Cling Films - Jumia Nigeria

Amazing Deals during Black Friday. Shop for Plastic Wrap & Cling Films online on Jumia Nigeria. Discover a great selection of Plastic Wrap ... 於 www.jumia.com.ng -

#75.plastic wrap 中文 - 查查在線詞典

plastic wrap 中文:保鮮膜…,點擊查查權威綫上辭典詳細解釋plastic wrap的中文翻譯,plastic wrap的發音,音標,用法和例句等。 於 tw.ichacha.net -

#76.Shrink Wrap & Pallet Wrap | Officeworks

Buy Shrink Wrap and Pallet Wrap at Officeworks. Shop online or in store and save with our Price Beat Guarantee. Buy in bulk and save. 於 www.officeworks.com.au -

#77.Plastic Wrap | Metro

Shop for groceries online at metro.ca! See all Plastic Wrap products in the Cooking & Kitchen Supplies aisle. 於 www.metro.ca -

#78.Plastic Wrap & Foil - CVS

Plastic wrap is a clear, thin, and pliable film that can be placed directly over food storage containers and bowls to keep the ingredients fresh. While this ... 於 www.cvs.com -

#79.Pallet Wrap & Stretch Films - Signet

Shop our extensive range of plastic wraps, pallet wraps and stretch films today! Protect and secure your packaging with plastic film ... 於 www.signet.net.au -

#80.PRO-SERIES 80-Gauge 18 in. x 1500 ft. Stretch Wrap Roll

Wrap pallets, furniture and more with the Buffalo Pallet Roll Stretch Wrap. Great for warehouses to wrap pallets and movers to wrap furniture to keep the ... 於 www.homedepot.com -

#81.The Real Reason Why Saran Wrap Doesn't Cling Anymore

In fact, changing the way Saran Wrap works came at a huge loss to the parent company, SC Johnson. The original wrap contained a chemical that's ... 於 www.delish.com -

#82.Different Types of Plastic Wraps and Their Usage

The plastic wraps used in food packaging is made from polyvinyl chloride which helps in maintaining the level of water vapour and oxygen in the ... 於 www.thongguan.com -

#83.Duck Brand Stretch Wrap, Clear, 20" x 1,000' - Sam's Club

Next time I'll order an industrial roll of plastic wrap for food and use that. Recommends this product; ✘ No. 於 www.samsclub.com -

#84.Un-Plastic Wrap - Green - Seed & Sprout Co

Home Compostable Un-Plastic Wrap has had an update! Un-plastic the planet with our high performance & certified home compostable cling wrap, now in green! 於 seedsprout.com.au -

#85.plastic wrap - Translation into Chinese - examples English

Hard cheeses, like cheddar or Parmesan, can be stored in plastic wrap or airtight containers. 切德干酪或帕尔马干酪等硬奶酪可以存放在塑料袋或密闭容器中。 於 context.reverso.net -

#86.Food Wraps | Glad

Plastic wrap has never looked so good! Discover our vast assortment of wraps to keep your food fresh and protected while giving it an eye-popping design. 於 www.glad.com -

#87.Plastic Wrap & Foil | DollarTree.com

Prevent food from sticking and keep it fresh with plastic wraps & foil. Stock up on aluminum foil, parchment paper, cling wrap, and other essentials great ... 於 www.dollartree.com -

#88.11 Clever Other Uses for Plastic Wrap - Bob Vila

But it may be time to take another look at some everyday household staples—like plastic wrap. That kitchen mainstay can be pressed into service in many ... 於 www.bobvila.com -

#89.Can You Reuse Plastic Wrap? - Taste of Home

It's important to repurpose, reuse and recycle. But can you reuse plastic wrap? Yes. Here are crafty ways to get more mileage out of every roll. 於 www.tasteofhome.com -

#90.It's Time to Ditch Your Plastic Wrap — Here's Why

There's no doubt that plastic wrap — also known as Cling Wrap or Saran Wrap — is convenient. However, it's super hard to reuse and ... 於 recyclinginlincoln.com -

#91.Publix Plastic Wrap, 200 Square Feet

Ideal for microwaving. Plastic wrap makes the perfect cover for microwave-proof ovenware. Some foods, particularly those containing fat or sugar, can become ... 於 www.publix.com -

#92.9 Plastic Wrap Alternatives - Apartment Therapy

9 Plastic Wrap Alternatives · 1. Glass Jars · 2. Tin Foil · 3. Glass or Plastic Food Storage Containers · 4. Oilcloth · 5. Parchment or Wax Cloth · 6. 於 www.apartmenttherapy.com -

#93.Plastic Wrap in Cleaning and Household Department - Fred ...

Shop for Plastic Wrap in our Cleaning and Household Department at Fredmeyer. Buy products such as Glad Cling Wrap for in-store pickup, at home delivery, ... 於 www.fredmeyer.com -

#94.The Plastic Wrap You Don't Need 3 Hands To Use | Bon Appétit

Forget those flimsy supermarket rolls of plastic wrap and treat your leftovers to the food service stuff. It's easier to use, stronger, ... 於 www.bonappetit.com -

#95.How to Recycle Your Business's Shrink Wrap | Rubicon

Shrink wrap recycling is a major part of our overall plastics recycling program at Rubicon®, meaning that if you're a business owner ... 於 www.rubicon.com -

#96.Learn What's Recyclable - Plastic Film Recycling

Bring These Items to a Drop-off Location for Recycling. Scroll through to view examples of plastic bags, wraps and film that can be recycled. 於 www.plasticfilmrecycling.org